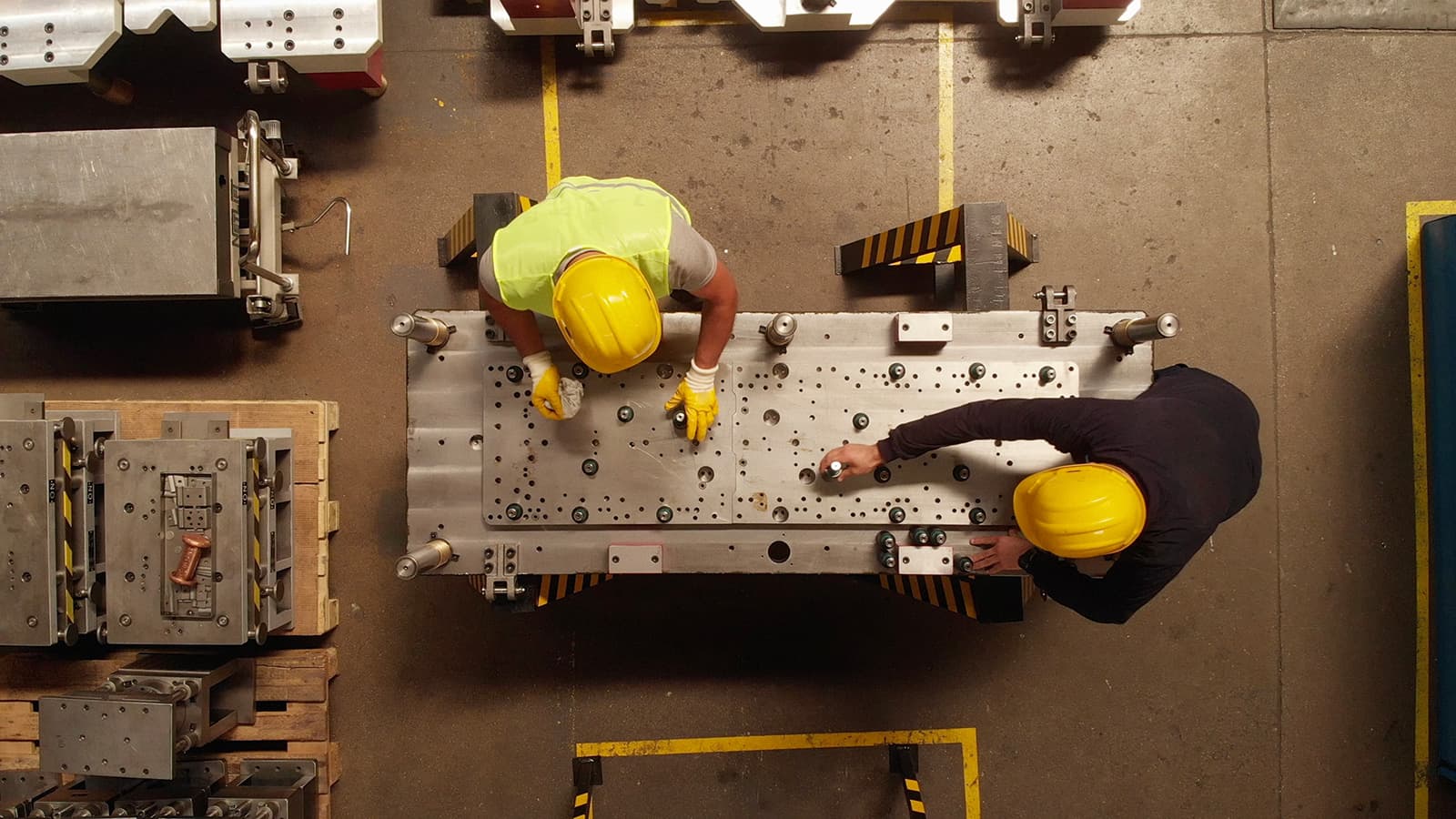

SINBON provides an extensive range of value-add engineering services that complement our complete end-to-end supply chain strategy — all of which are proven to reduce cost and accelerate time to market. First, our design and engineering teams bring value to the product development process, working at virtually every stage of the design cycle: from concept through detailed design and prototyping to volume production.

DESIGN FOR MANUFACTURING (DFM)

SINBON's engineers routinely use DFM to ensure consistent manufacture and allow any potential problems to be fixed in the design phase. DFM can reduce many costs, since products can be quickly assembled from fewer parts through standardisation and maximum use of purchased parts, modular design and standard design features. Prior to sampling stage SINBON will always submit a DFM to ensure our customer's needs are met and engineering options are explored. As well as electrical and mechanical design, the DFM will also include 3D modelling.

MECHANICAL AND ELECTRICAL DESIGN

SINBON has over 200 R&D engineers that help bring our customers designs and concepts to market. Our services include,

- Mechanical Design and modelling

- Hardware Design

- RF design and modelling

- 3D printing for prototyping

- PCB layout design

- Embedded system design

- Firmware design and integration

NPI & PROJECT MANAGEMENT

We offer a comprehensive new product Introduction (NPI) process that combines our specialised engineering and manufacturing services along with dedicated project management support. Working in common time zones and languages, we ensure exceptional customer service and technical support throughout the entire manufacturing process.

Our dedication to providing reliable electronics solutions means that real-time and in-depth support is a crucial part of our offering. We are here to help you take your products from conceptual design through to volume production.